1. FEATURES

(1) This machine may be used for surface cutting, drilling, milling, and tapping.

(2) This machine is of fine quality, can be operated easily, it is not limited to skilled operator.

(3) The drilling and milling operation can be performed by two methods:

1) Hand operation, which makes quick feeding drilling.

2) Worm gear feed operation, which makes slow feeding milling.

(4) Many of the adjustable nuts are bronze, for adjusting thread clearance and reducing wear. these bronze parts also allow screws to rotate smoothly and improve accuracy.

(5) The vertical column is very strong and stiff, which makes the machine very stable and improves accuracy of manufactured parts.

(6) The machine headstock is cast iron, it has been heat-treated, stress-relieved, and precision machined.

(7) Machine gears are precision ground for smooth operation.

(8) Speeds can be easily changed.

(9) Tapping can be done in either rotation, working depth can be controlled by using a positive stop gauge.

(10) The head can be turned in two rotation for a satisfying desired angle.

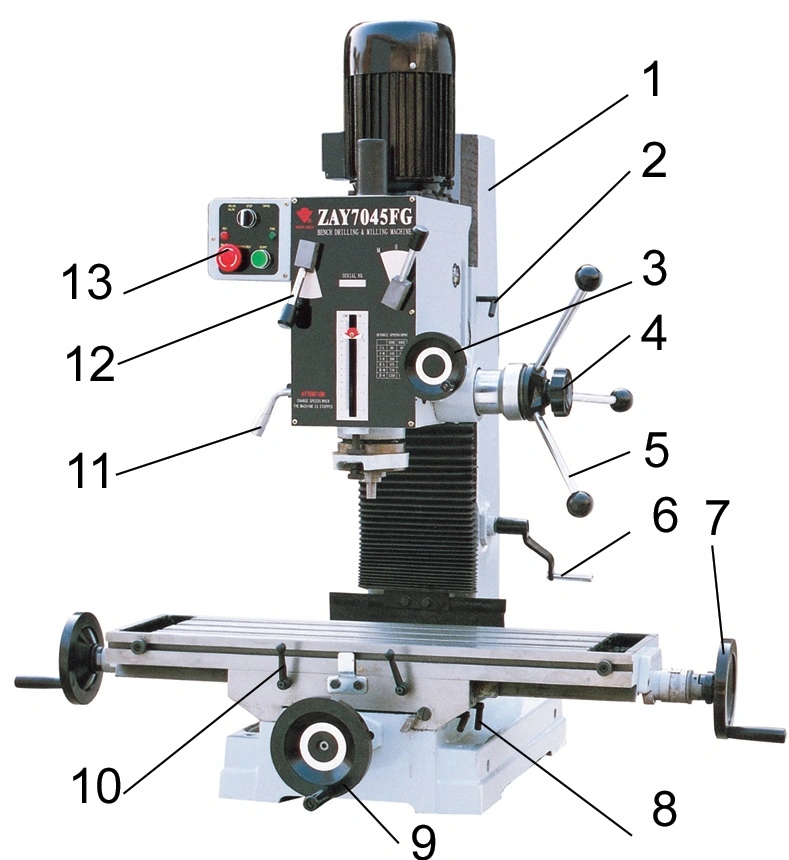

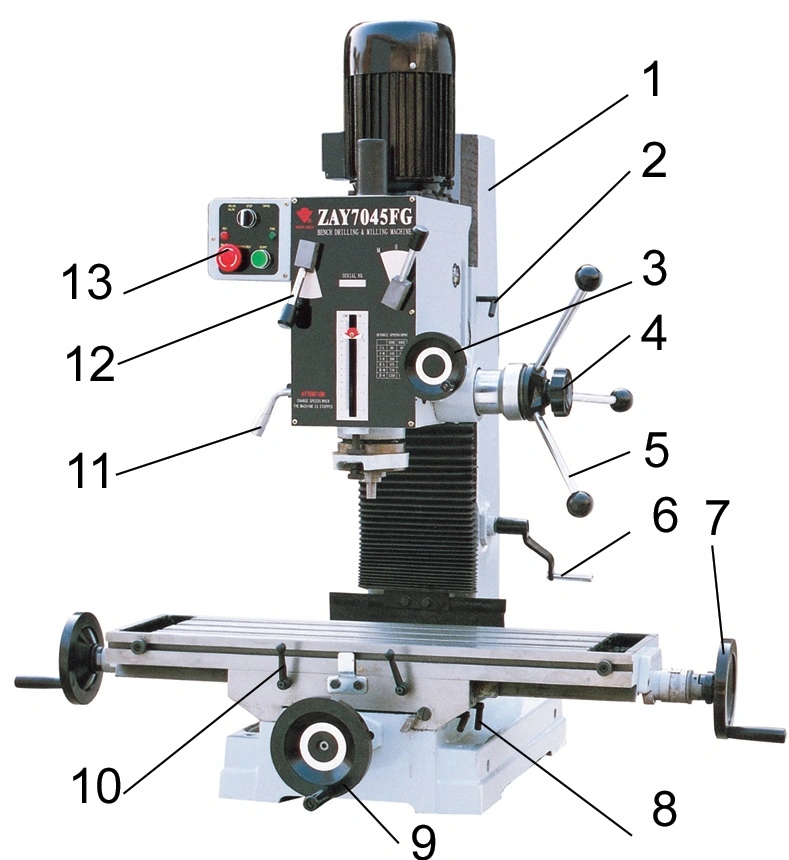

1.square column 2.lock screw 3.micro feed handwheel

4.lock handle 5.feed handle 6.crank 7.handwheel

8.cross lock screw 9. longitudinal lock screw 10.lock handle 11.shift handle 12.change speed handle 13.switch

Standrad accessories:Allen wrench, Wedge-Wrenches, Drill chuck arbor, screw, draw bar and washers

Optional accessories:

1.Machine stand

2.Power feed

3.90mm paraller vise

4.120mm paraller vise

5.Drill chuck

6.milling cuttter holder

7.Changing sleeve

8.Mill chuck

9.Auto-tapping electrical

10.Boring bar

11.Working lamp

12.Coolant system

13.DRO/XY

3.Machine photos

4.Manufacturing Capability

(1) This machine may be used for surface cutting, drilling, milling, and tapping.

(2) This machine is of fine quality, can be operated easily, it is not limited to skilled operator.

(3) The drilling and milling operation can be performed by two methods:

1) Hand operation, which makes quick feeding drilling.

2) Worm gear feed operation, which makes slow feeding milling.

(4) Many of the adjustable nuts are bronze, for adjusting thread clearance and reducing wear. these bronze parts also allow screws to rotate smoothly and improve accuracy.

(5) The vertical column is very strong and stiff, which makes the machine very stable and improves accuracy of manufactured parts.

(6) The machine headstock is cast iron, it has been heat-treated, stress-relieved, and precision machined.

(7) Machine gears are precision ground for smooth operation.

(8) Speeds can be easily changed.

(9) Tapping can be done in either rotation, working depth can be controlled by using a positive stop gauge.

(10) The head can be turned in two rotation for a satisfying desired angle.

4.lock handle 5.feed handle 6.crank 7.handwheel

8.cross lock screw 9. longitudinal lock screw 10.lock handle 11.shift handle 12.change speed handle 13.switch

| SPECIFICATION | ||||

| Model | ZX-45 | |||

| Max.drilling capacity | 45mm | |||

| Max.face mill capacity | 80mm | |||

| Max.end mill capacity | 28mm | |||

| Max.tapping capacity | M12 | |||

| Max.spindle stroke | 130mm | |||

| Max.distance from spindle axis to | 260mm | |||

| column | ||||

| Swivel angle of headstock at perpendicular direction | ±90° | |||

| Max.distance between spindle nose to table | 450mm | |||

| Spindle taper | M.T.4 OR R8 | |||

| Working area of table | 800mm×240mm | |||

| Forward and backward travel of table | 175mm | |||

| Left and right travel of table | 400mm or 500mm | |||

| Spindle speeds (4P) | 50HZ: 80,145,260,375,710,1250 RPM | |||

| 60HZ: 95,175,310,450,850,1500 RPM | ||||

| Motor | 1.5KW (1HP) | |||

| Length | 820mm | |||

| Width | 160mm | |||

| Overall height (without stand) | 1020mm | |||

| Net weight/gross weight | 325kg/375kg | |||

Standrad accessories:Allen wrench, Wedge-Wrenches, Drill chuck arbor, screw, draw bar and washers

Optional accessories:

1.Machine stand

2.Power feed

3.90mm paraller vise

4.120mm paraller vise

5.Drill chuck

6.milling cuttter holder

7.Changing sleeve

8.Mill chuck

9.Auto-tapping electrical

10.Boring bar

11.Working lamp

12.Coolant system

13.DRO/XY

3.Machine photos

4.Manufacturing Capability