1. FEATURES

Specification

Standrad accessories:Allen wrench, Wedge-Wrenches, Drill chuck arbor, screw, draw bar and washers

Optional accessories:

1.Machine stand

2.Power feed

3.90mm paraller vise

4.120mm paraller vise

5.Drill chuck

6.milling cuttter holder

7.Changing sleeve

8.Mill chuck

9.Auto-tapping electrical

10.Boring bar

11.Working lamp

12.Coolant system

13.DRO/XY

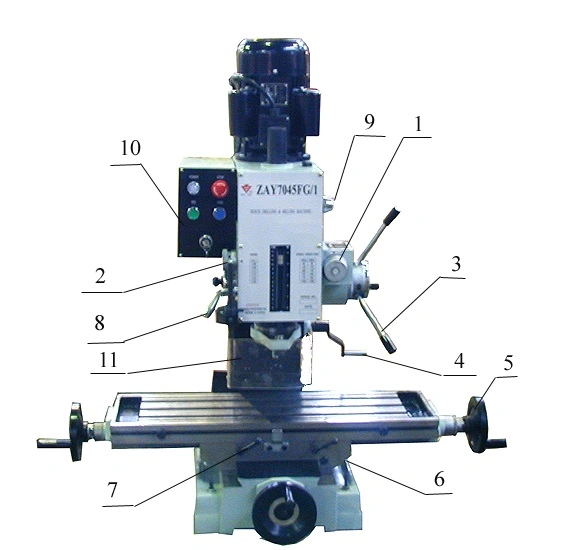

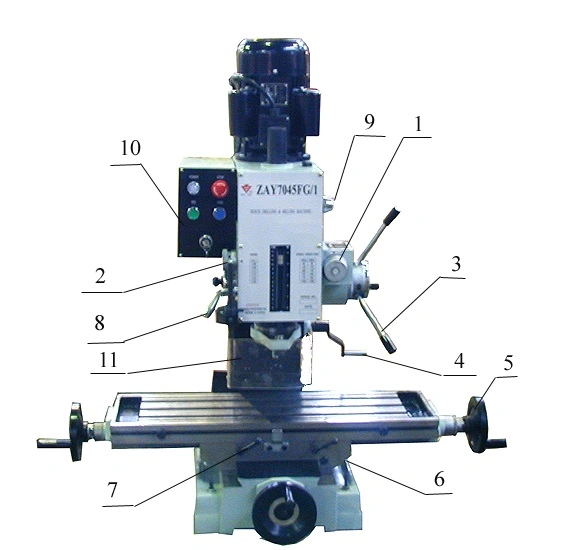

3.Machine photos

4.Manufacturing Capability

- This machine may be used for surface cutting,drilling,milling,and tapping.

- This machine is of fine quality,can be operated easily, it is not limited

- The drilling and milling operation can be performed by two methods:

- Hand operation,which makes quick feed drilling.

- Worm gear feed operation,which makes slow feed milling.

- Many of the adjustable nuts are bronze,for adjusting thread clearance and reducing wear.these bronze parts also allow screws to rotate smoothly and improve accuracy.

- The vertical column is very strong and stiff,which makes the machine very stable and improves accuracy of manufactured parts.

- The machine head is cast iron, it has been heat-treated,stress-relieved,

- Machine gears are precision ground for smooth operation.

- Speeds can be easily changed.

- Tapping can be done in either rotation,working depth can be controlled by using a positive stop gauge.

- micro-feeding knob 2. Auto-feeding knob 3.feeding handle 4.crank 5.handwheel 6.cross lock screw 7. Longitudinal lock screw 8.lock handle 9.shift handle 10.switch 11.Guard

Specification

| Model | ZAY7032FG/1 | ZAY7040FG/1 | ZAY7045FG/1 | ||

| Max.drilling capacity | E32mm | E40mm | E45mm | ||

| Max.face mill capacity | E63mm | E80mm | |||

| Max.end mill capacity | E28mm | E32mm | |||

| Max.tapping capacity | M12 | ||||

| Max.spindle stroke | 130mm | ||||

| Headstock axial stroke | 400mm | ||||

| Swivel angle of headstock at perpendicular direction | ±90° | ||||

| Max.distance between spindle nose to table | 450mm | ||||

| Spindle taper | M.T.3 OR R8 | M.T.4 OR R8 | |||

| Distance between spindle to slide | 286mm | ||||

| Working area of table | 800mm×240mm | ||||

| Forward and backward travel of table | 175mm | ||||

| Left and right travel of table | 500mm | ||||

| Spindle speeds (4P) | 50HZ 80,145,260,375,710,1250 RPM | ||||

| 60HZ 95,175,310,450,850,1500 RPM | |||||

| Feed steps | 6 | ||||

| Feed range(mm/r) | 0.06, 0.09, 0.12, 0.15, 0.18, 0.30 | ||||

| Motor | 0.75KW (1HP) | 1.5KW (2HP) | 1.5KW (2HP) | ||

| Length | 820mm | ||||

| Width | 1160mm | ||||

| Overall height (without stand) | 1060mm | ||||

| Net weight/gross weight | 320kg/370kg | 323kg/373kg | 325kg/375kg | ||

Standrad accessories:Allen wrench, Wedge-Wrenches, Drill chuck arbor, screw, draw bar and washers

Optional accessories:

1.Machine stand

2.Power feed

3.90mm paraller vise

4.120mm paraller vise

5.Drill chuck

6.milling cuttter holder

7.Changing sleeve

8.Mill chuck

9.Auto-tapping electrical

10.Boring bar

11.Working lamp

12.Coolant system

13.DRO/XY

3.Machine photos

4.Manufacturing Capability